SIMPLE LIFTING MACHINES

LIFTING MACHINES

-

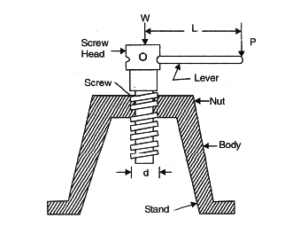

SIMPLE SCREW JACK:

A screw jack is one of the simple lifting machines which is used to lift a heavy load by applying smaller effort. It consists of a screw, fitted in a nut, which forms the body of the jack and a screw head to which a handle is attached. The load is kept on the screw head and effort is applied by the handle. The screw jack works on the same principle on which an inclined plane works. In one revolution of the handle, screw rotated by one revolution. Then load raised is equal to the pitch of the screw.

Let,

W = Load to be lifted

P = Effort required to lift the load at the end of the handle

L = Length of the handle

p = Pitch of the screw

In one revolution of the screw,

Distance moved by the effort = 2πL

Distance moved by the load = p

∴ Velocity Ratio (V.R) = [frac up=”Distance moved by the effort” down=”Distance moved by the load”] = [frac up=”2πL” down=”p”]

Mechanical Advantage (M.A) = [frac up=”Load” down=”Effort”] = [frac up=”W” down=”P”]

Efficiency, η = [frac up=”M.A.” down=”V.R.”] = [frac up=”W/P” down=”2πL/p”]

η = [frac up=”W x p” down=”P x 2πL”]

-

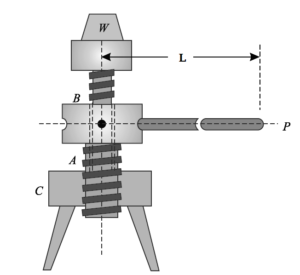

DIFFERENTIAL SCREW JACK:

It is an improved form of a simple screw Jack in which the velocity ratio is intensified with the help of a differential screw. The principle on which this machine works, is the same as that of any other differential machine, i.e., action of one part of the machine is subtracted from the action of another part.

In this machine, the differential screw is in two parts, A and B. Part A is threaded both on inside and outside ; whereas the part B is threaded on the outside only. The external threads of A gear with the threads of the nut C, which forms the body of the differential screw jack. The internal threads of A gear with the external threads of the screw B. Thus the part A behaves as a screw for the nut C and as a nut for the screw B.

Let,

W = Load to be lifted

P = Effort required to lift the load at the end of the handle

p1 = Pitch of screw A,

p2 = Pitch of screw B,

L = Length of the handle

In one revolution of the screw,

Distance moved by the effort = 2πL

Upward distance moved by A = p1

Downward distance moved by B = p2

∴ Velocity Ratio (V.R) = [frac up=”Distance moved by the effort” down=”Distance moved by the load”] = [frac up=”2πL” down=”p1 – p2“]

Mechanical Advantage (M.A) = [frac up=”Load” down=”Effort”] = [frac up=”W” down=”P”]

Efficiency, η = [frac up=”M.A.” down=”V.R.”] = [frac up=”W/P” down=”2πL/(p1 – p2)”]

η = [frac up=”W x (p1 – p2)” down=”P x 2πL”]

-

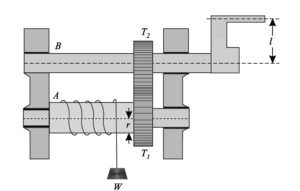

SINGLE PURCHASE CRAB WINCH

It is one of the simple lifting machines which consists of a small wheel gearing with a large wheel , the small wheel is called pinion and the large wheel is called spur wheel. The spur wheel is connected with a load drum of radius (r). One end of rope is fixed to drum and wounded around the drum. The free end of rope carries a load (W). Effort pulley of radius (R) is connected with spindle carrying the pinion. The effort is applied on effort pulley.

Let,

W = Load lifted

P = Effort required

l = Length of handle

r = Radius of load drum

T1 = Number of teeth on pinion

T2 = Number of teeth on spur wheel

In one revolution of effort pulley the distance moved by effort is 2πR (in cm).

In one revolution of load pulley the distance moved by load is 2πr (in cm).

In one revolution of effort pulley the pinion will make one revolution while spur wheel will make [frac up=”T1” down=”T2“] of a revolution, the load drum will also make [frac up=”T1” down=”T2“] of revolution.

Distance moved by load = [frac up=”T1” down=”T2“] x 2πr

∴ Velocity ratio = [frac up=”Distance moved by effort” down=”Distance moved by load drum”]

Velocity ratio = [frac up=”2πrR” down=”(T1/T2)2πr”] = [frac up=”T2” down=”T1“] x [frac up=”R” down=”r”]

Mechanical Advantage = [frac up=”Load” down=”Effort”] or [frac up=”W” down=”P”]

Efficiency = [frac up=”Mechanical Advantage” down=”Velocity Ratio”] = [frac up=”M.A” down=”V.R”] = [frac up=”W/P” down=”(T2/T1) x (R/r)”]

-

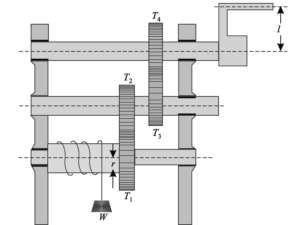

DOUBLE PURCHASE CRAB WINCH:

A double purchase crab winch is an improved form of a single purchase crab winch, in which the velocity ratio is intensified with the help of one more spur wheel and a pinion.

This winch consists of two pairs of gears and three axles (effort axle, load axle and intermediate axle). On the effort axle, a pinion is attached whereas on the load axle a spur wheel is attached. The pinion of intermediate axle gears with the spur wheel of the load axle. Spur wheel of the intermediate axle gears with the pinion of the effort axle. The load is applied in the load drum with the help of rope whereas effort is applied by handle.

Let,

W = Load lifted

P = Effort required

l = Length of the handle

r = Radius of load axle

T1 = Number of teeth in the pinion of the effort axle

T2 = Number of teeth in the spur wheel of the intermediate axle

T3 = Number of teeth in the pinion of intermediate axle

T4 = Number of teeth in the spur wheel of load axle

Let the handle be rotated once, the distance moved by the effort = 2πR

In one revolution of the effort axle, the spur wheel of intermediate axle will make [frac up=”T1” down=”T2“] of a revolution and the number of revolution made by spur wheel of the load axle = [frac up=”T1” down=”T2“] = [frac up=”T3” down=”T4“]

Hence the distance moved by the load = 2πR x [frac up=”T1” down=”T2“] x [frac up=”T1” down=”T2“] = [frac up=”T3” down=”T4“]

∴ Velocity ratio = [frac up=”Distance moved by effort” down=”Distance moved by load drum”]

Velocity ratio = [frac up=”2πrR” down=”(T1/T2) x (T3/T4) x 2πr”] = [frac up=”T2” down=”T1“] x [frac up=”T4” down=”T3“] x [frac up=”R” down=”r”]

Mechanical Advantage = [frac up=”Load” down=”Effort”] or [frac up=”W” down=”P”]

Efficiency = [frac up=”Mechanical Advantage” down=”Velocity Ratio”] = [frac up=”M.A” down=”V.R”] = [frac up=”W/P” down=”(T2/T1) x (T4/T3) x (R/r)”]

RELATED VIDEOS: