FITTING SHOP

HOLDING TOOLS USED IN ENGINEERING WORKSHOP

Holding tools are also known as Work Holding devices in the Fitting workshop. They are used to hold all types of components between jaws (Fixed Jaw and Movable Jaw).

The Various Work holding devices are

- Bench Vice

- Hand Vice

- Pipe Vice

- Leg Vice

- Pin Vice

- Toolmakers Vice

The Explanation for the Work Holding Devices is as follows:

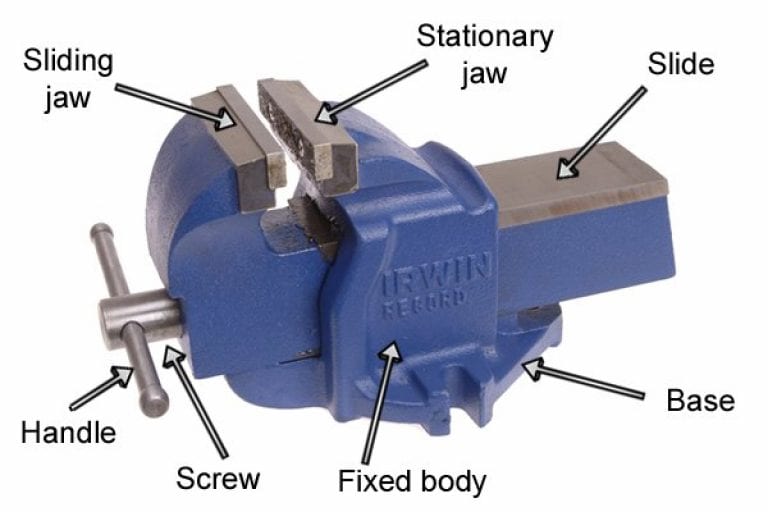

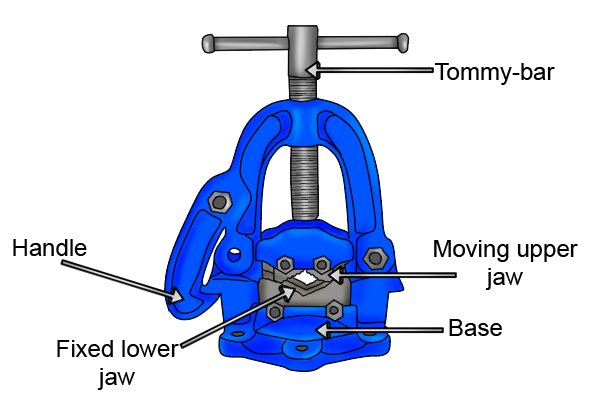

BENCH VICE:

Bench Vice is a holding tool which is used to hold the specimen or the workpiece between the two jaws and is firmly fixed to the bench with bolts and nuts. It consists of an iron or steel cast body, square threaded screw, nut, handle, two jaws and jaw plates.

Parts of Bench Vice

One of the two jaws is stationary, while the other jaw is movable which can be brought close on the work by rotating the square threaded screw in the nut. The jaw plate are knurled on one side and fixed in the jaws with the help of the screws and can be replaced when worn out. The knurling is done to help in gripping the work. For holding soft material or finished work, soft plate liners or coverings made of lead, fiber, copper, brass or tin plate are fitted over the jaws for giving protective grip in order to prevent the surface of the finished work from damaging.

The height of the bench should be such that the top of the vice jaws is at about the same height as the operator’s elbow.

The size of the vice is given by the width of the jaws and the maximum opening between the jaws.

For gripping the work in the vice the jaws are opened out by withdrawing the movable jaw by rotating the screw, the work is held between the jaws by one hand and the screw is tightened by rotating the handle by other hand. This brings the two jaws closer and ultimately the work is gripped between the jaws. The desired pressure on the work is attained by tightening and loosening the screw, depending upon the need. The work held in this vice may be of any regular or irregular shape and a desired amount of grip can be applied. The parallel jaws of the vice enable the work to be held square so that fitting, scrapping and chipping operations can be performed easily.

Parts of Bench Vice with Explanation:

Jaws:

The Jaws are used to hold the workpiece by rotating the handle. In that, one jaw is fixed and the other is movable.

Body:

All the parts like a handle; jaws etc. are connected to the body of a bench vice.

Handle:

If the handle is rotated in clockwise direction, then the workpiece is fixed between two jaws. If the handle is rotated in counterclockwise direction, then the work piece is loosened from the jaws.

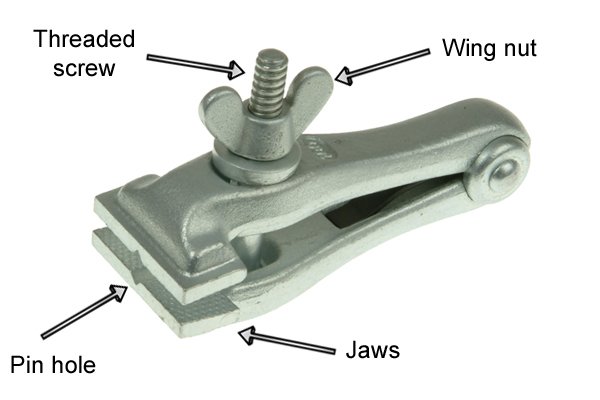

HAND VICE:

For gripping very small objects a Hand Vice is used. It consists of two steel legs hinged together at the bottom and carrying the hardened steel jaws at the other end. A spring attachment is provided between the two legs, which always tend to keep the jaws separate. A screw is fastened to one leg and passes through the other. At the free end of the screw a Wing Nut is provided. The piece to be held is gripped between the serrated jaws by tightening the wing nut.

The vice is held in one hand and the required operation is performed by the other hand. The wing nut is tightened in clockwise direction to hold the workpiece and loosened in counterclockwise direction. It issued for griping small objects such as screws, rivets, small drills, keys of locks and other similar objects which are too small to be conveniently held in bench vice.

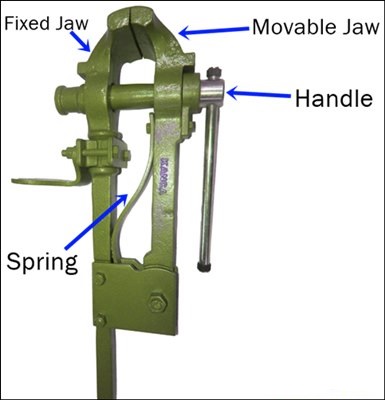

LEG VICE:

It is generally used for heavy hammering, chipping and cutting in fitting shop. The vice is secured to the top of the bench by an iron strap which is fastened to a plate bolted to the bench top. It differs from the bench vice in that the movable jaw is pivoted about a point near to the middle of the leg of the vice. This prevents the faces of the two jaws from being parallel to each other in every position except one position.

PIPE VICE:

Pipe Vice is used for holding pipes, shafts or round jobs. It works on the same principle as the bench vice. It consists of two jaws, one of which is fixed and other is movable. The shape of the jaws is like a V and it grips the work at four points of its surface.

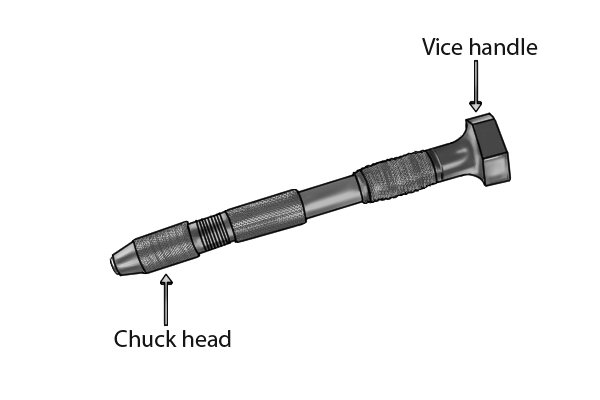

PIN VICE:

Pin vice is used for holding very small pieces like wire, nails, pins etc. It is a small form of collet chuck. It consists of a handle and a tapered nose carrying a small collet chuck at its end. The collet carries three hardened steel jaws which are operated by rotating the handle. The piece to be held is inserted between the jaws, the handle rotated and thus it is gripped in the collet.

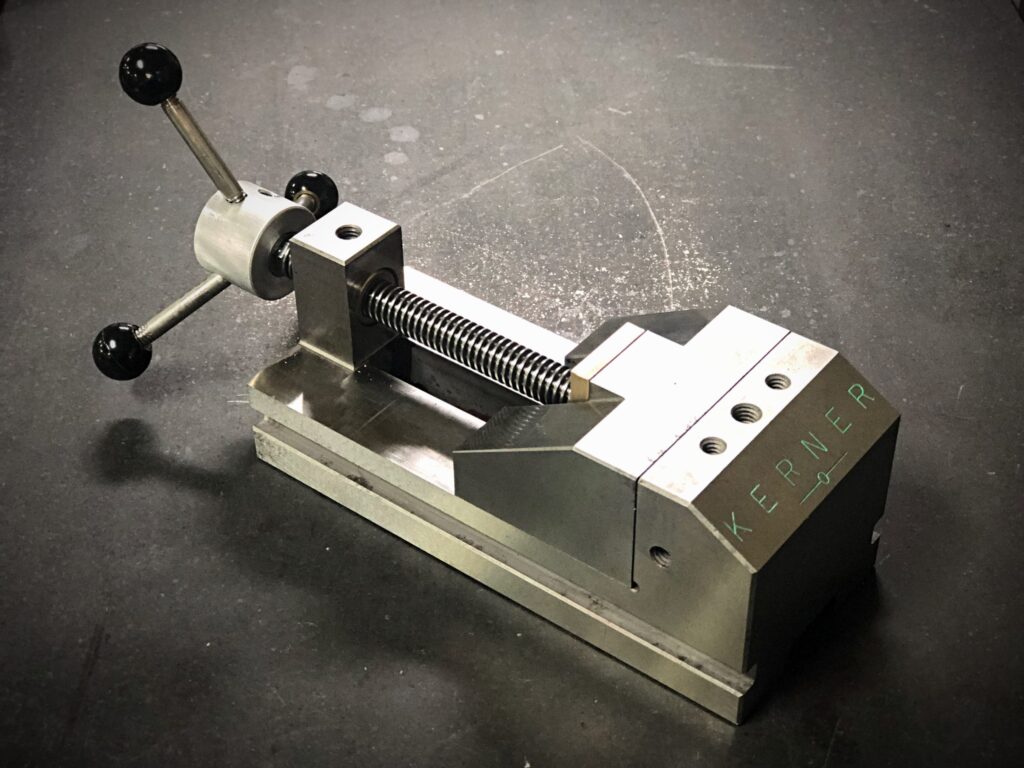

TOOL MAKER’s VICE:

Tool Maker’s Vice is used for holding small work for filing or drilling. It consists of a U shaped body carrying a screw in one limb. A metal block is placed between the end face of the screw and the other limb of the body. The piece is gripped between the surface of this block and the free limb of the body by the toolmakers for small machining operations like drilling or tapping etc.

RELATED VIDEOS FOR WORK HOLDING DEVICES:

https://drive.google.com/open?id=14hup5GVUJflTMVqk6fZhPbVuueVfoWb-&authuser=0

For More Information- CLICK HERE