OPERATIONS MANAGEMENT

MASTER PRODUCTION SCHEDULE (MPS):

Master Production Schedule (Master Production Scheduling) is a plan for the production of individual final items. The MPS breaks down the production plan to show, in each period, the quantity to produce of each final article. Each final article is also called Stock Keeping Unit, usually using its acronym SKU. The Master Production Program, which is developed over a period of time, is called the planning horizon. The planning horizon generally extends between 3 and 18 months, depending on the manufacturing cycles of the item in question.

Master Production Scheduling

- MPS focuses on a specific time period. It includes a plan for the production of individual commodities such as staffing, inventory etc. for the allotted time period.

- An MPS usually dictates when and how much of each product is demanded, in addition to a statement of what they expect to produce and purchase.

- MPS aids in decision making by generating a set of output data based on forecast demand, production costs, inventory money, customary need, production lead time time and capacity. The resulting output information incudes the amount to produce, staffing requirements, quantity of product available to promise and projected available funds for production.

- It forms the link between production planning and what manufacturing will actually build.

- It forms the basis for calculating the capacity and resources needed.

- The MPS drives the material requirements plan.

- It keeps priorities valid. The MPS is a priority plan for manufacturing.

- The end items made by the company are assembled from component and subcomponents parts. These must be available in the right quantities at the right time to support the master production schedule. The material requirements planning system plan the schedule for these components based on the needs of the MPS.

- The MPS is a plan for manufacturing. It reflects the needs of the marketplace and the capacity of manufacturing and forms a priority plan for manufacturing to follow.

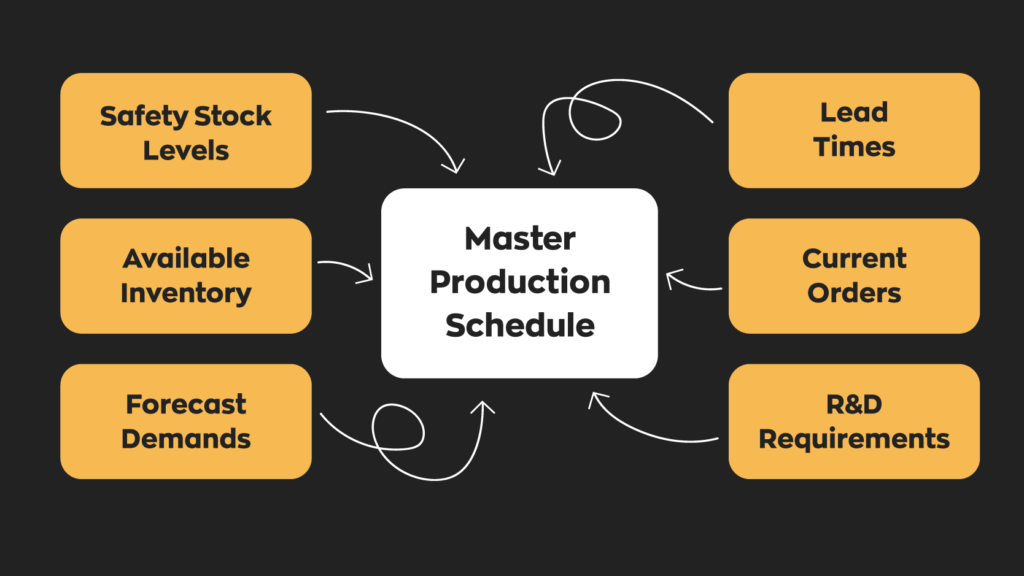

The input data feeding the Master Production Schedule is the following:

- Aggregate production plan, in product units.

- The forecast of each final article, in product units.

- The current order portfolio.

- The stock inventory level.

- The available production capacity.

OBJECTIVES OF MASTER PRODUCTION SCHEDULING:

- Keeping the inventories.

- Setting up the due dates for the availability of items.

- Maintaining the customer service.

- Setting proper schedules.

FUNCTIONS OF MASTER PRODUCTION SCHEDULING :

- Specifies planning periods as daily, weekly or monthly.

- Group work order processing.

- Tracks accuracy of order forecasting as percentage.

- Classifies supply into types such as materials, purchased, flow, work order and transfer.

- Schedule can be edited, changed or consolidated.

RELATED VIDEO: